News

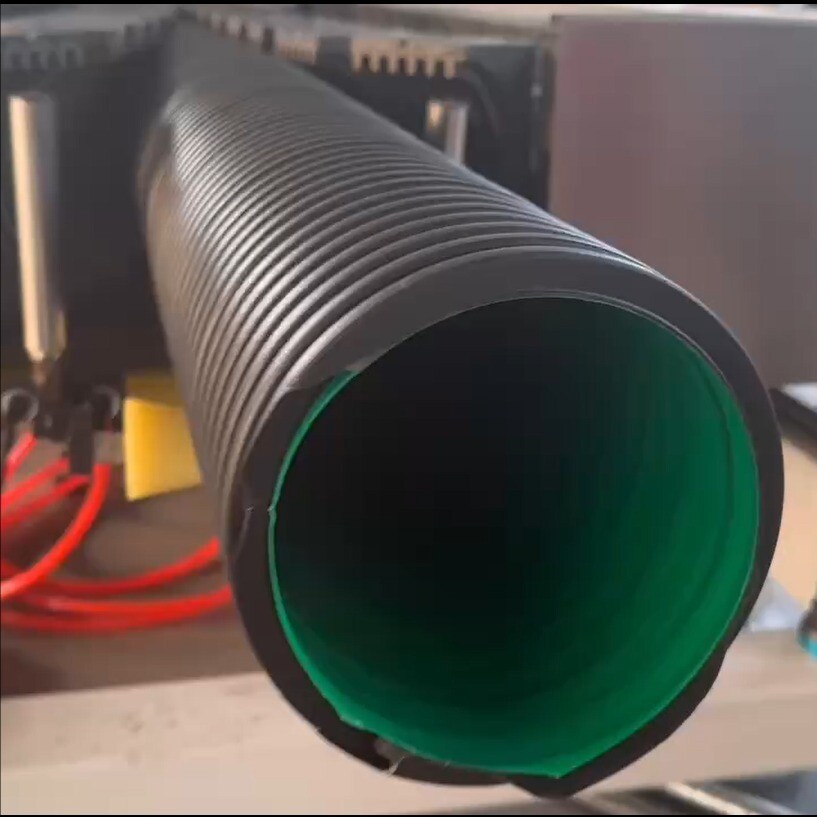

The double-wall corrugated pipe equipment mainly consists of an extruder, a molding machine, a cooling system, a cutting machine and a control system, and is used to produce double-wall corrugated pipes with raw materials such as HDPE, PP or PVC.

Extruder: It is responsible for heating and melting the plastic raw materials (such as HDPE, PP, PVC) and uniformly extruding them. It is one of the core equipment in the production line.

Mold head and mold of the molding machine: The mold head has high precision and good module interchangeability. It is cooled by water or air cooling and can achieve online expansion, ensuring the performance indicators such as ring stiffness and inner wall smoothness of the pipe.

Vacuum sizing and cooling system: It includes a vacuum sizing box and a water cooling tank, used to control the pipe diameter and perform preliminary cooling, ensuring the dimensional accuracy and surface quality.

Cutting machine: It has excellent cutting accuracy and can cut the continuously produced pipe into fixed lengths as needed.

Traction and stacking system: It consists of a traction machine and a stacking machine, responsible for uniformly pulling out the pipe and neatly stacking the finished products. Control System: Typically, Siemens PLC human-machine interface is adopted to achieve the automatic control and parameter setting of the entire production line.

Awesome! Share to:

Related Posts

- Krah pipe production line - Quality first

- Characteristics of Single-wall corrugated pipe production line

- The PVC/WPC door frame production line is ready for shipment

- The PE pipe production equipment is under trial operation

- In the production of corrugated pipe equipment, it is characterized by high speed and efficiency

First class quality service and professional after-sales team.

In order to provide you the suitable machine , pls offer below message for us

Get in Touch

We respect your confidentiality and all information are protected.